Knife Style Perforator

Description

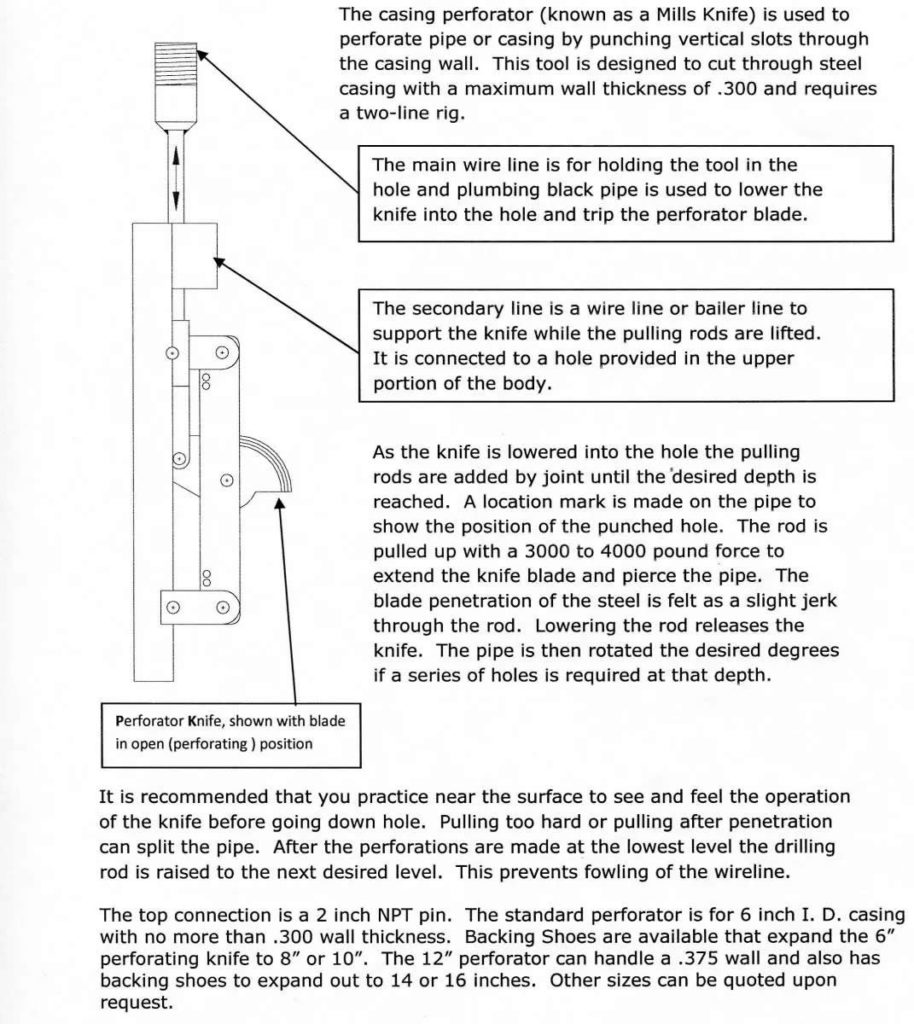

The casing perforator is used to perforate pipe or casing by punching vertical slots through the casing wall. This tool is designed to cut through steel casing with a maximum wall thickness of .300 and requires a two-line rig. The main wire line is for holding the tool in the hole and plumbing black pipe is used to lower the knife into the hole and trip the perforator blade. The secondary line is a wire line or bailer line to support the knife while the pulling rods are lifted. As the knife is lowered into the hole the pulling rods are added by joint until the desired depth is reached. A location mark is made on the pipe to show the position of the punched hole. The rod is pulled up with a 3000 to 4000 pound force to extend the knife blade and pierce the pipe. The blade penetration of the steel is felt as a slight jerk through the rod. Lowering the rod releases the knife. The pipe is then rotated the desired degrees if a series of holes is required at that depth. It is recommended that you practice near the surface to see and feel the operation of the knife before going down hole. Pulling too hard or pulling after penetration can split the pipe. After the perforations are made at the lowest level the drilling rod is raised to the next desired level. This prevents fowling of the wireline. The top connection is a 2″ NPT pin. The standard perforator is for 6″ I. D. casing with no more than .300″ wall thickness. Backing Shoes are available that expand the 6″ perforating knife to 8″ or 10″. The 12″ perforator can handle a .375″ wall and also has backing shoes to expand out to 14″ or 16″. Other sizes can be quoted upon request.