Drag Bits

What is a drag bit?

This kind of bit uses the action of the stem rotation to drag the bit over the surface of the formation. With softer formations, like sand, clay, or soft rock, which is found throughout the Country, a drag bit loosens the material sufficiently for the drilling process to proceed. This bit does not work well on layers with coarse gravel or hard rock formations.

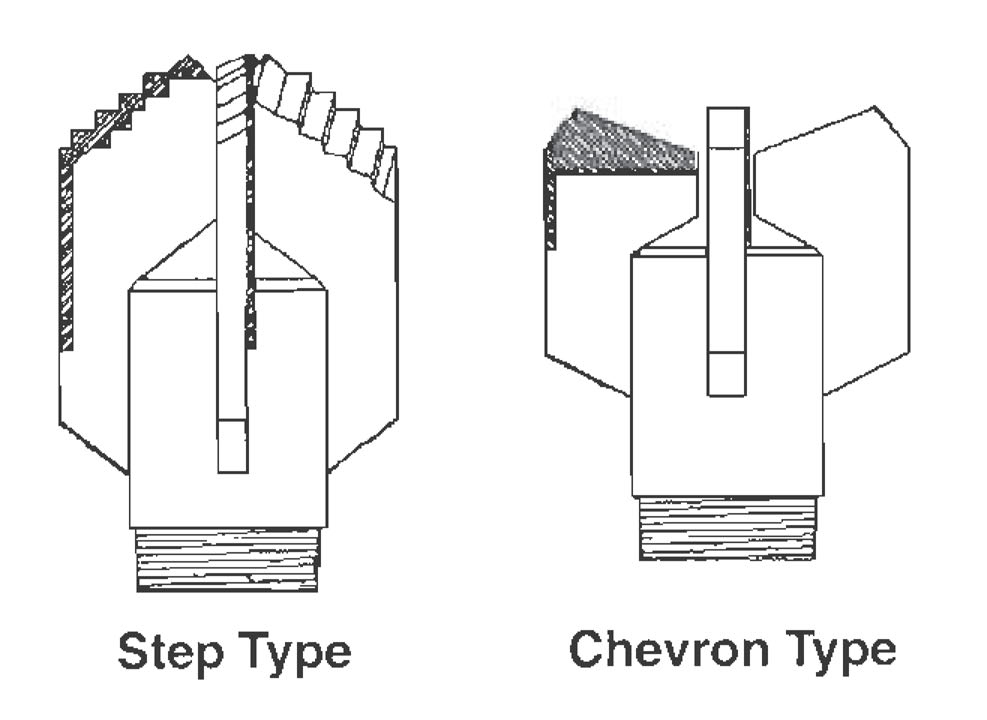

Drag bits have a wide range of drilling applications including environmental, exploration, geothermal, water well, road construction, and natural gas and oilfield drilling. The best application for these types of drill bits is softer, unconsolidated formations like clays, shale, sands, and soft limestone. The most common styles are either step type or chevron type bits.

Step Drag Bit

NDS Stocks Several Step Drag Bits that are Available on NDS’s Online Store. Drill overburdens with sands, clays and soft-formations with a step drag bit. The more aggressive cutting structure will produce larger cuttings than a chevron style bit and with higher Rate of Penetration (ROP). However, the downside is that it’s less durable than a Chevron Drag Bit. For best drilling results, maintain rotary speeds between 60 and 80 rpm with light weight on bit.

Chevron Drag Bit

Drill more abrasive formations, like soft sandstones and shales, with a chevron type bit. The cutting structure is more durable than the step style bit but will also penetrate more slowly. For best drilling results, maintain rotary speeds between 50 and 60 rpm with light to medium weight on bit (WOB). Harder formations require more WOB.